SemiLEDs MvpLED Technology

MvpLEDTM

![]()

SemiLEDs LEDs with the patented unique MvpLEDTM structure are revolutionizing the LED industry in terms of performance, quality, reliability and environmental awareness.

The specific advantages of using SemiLEDs LEDs are based on;

Quality by Design

Reliability

Greenest LEDs

Quality by Design

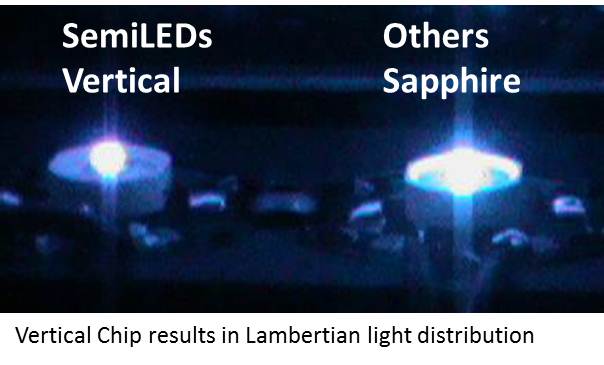

The advantages of the patented and proprietary MvpLED™ design especially in Thermal management, and Optical efficacy, are realized in light quality, lifetime, color consistency, reliability and overall efficiency of the luminaire.

Available in Blue, Green and Ultraviolet (UV), SemiLEDs high efficiency chips bring real benefits to any lamp or luminaire manufacturer.

Thermal Advantages:

Among pure metals at room temperature, copper has the second highest electrical and thermal conductivity after silver. Furthermore, due to the high thermal conductivity of the copper alloy layer, the heat generated in the SemiLEDs device is effectively conducted. This is a major advantage for any lamp or luminaire manufacturer. No matter how good a thermal design is if the contact material to the junction is a poor conductor then the cooling effects of the heat-sink are significantly reduced.

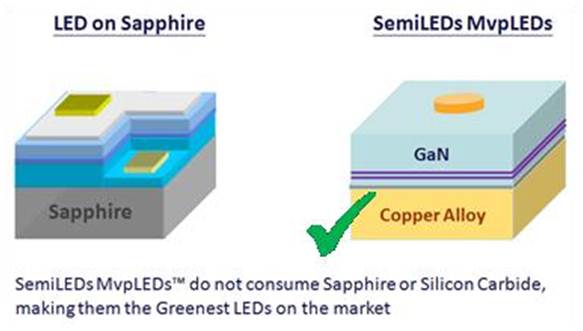

Greenest LEDs

Most LEDs are built on Sapphire wafers. On average, more than 200 kWh of electricity are spent on making a 2 inch Sapphire wafer; a significant environmental burden.

Other manufacturers dice the LEDs without removing the Sapphire.

Sapphire is a less effective conductor of heat acting as a bottleneck for heat transfer from the junction to the heat-sink.

The Sapphire wafer is also lost.

SemiLEDs’ patented and unique process consumes no Sapphire, significantly reducing the Carbon footprint.

The lack of Sapphire also removes a thermal management bottleneck while providing the most environmentally friendly LED on the market.

Reliability

Reliability and consistency are extremely important characteristics of an LED.

Any designer looking to design an LED into a lighting system should consider not only how the LED will perform on hour 1 but also on hour 1k, 10k and 100k.

It is evident that most LED deterioration is due to poor thermal management.

Excessive heat at the junction can damage the crystal quality, the bond pads, and even alter the chemistry of a Phosphor or an encapsulant material thus making it less transparent.

As a general rule of thumb, the more efficiently you can drive heat away from an LED, the more consistent and more reliable your lighting system will be.

SemiLEDs patented MvpLEDTM design maximizes the efficacy of any thermal management system by maximizing the heat transfer rate from the junction to the LED package.

Many thermal designs are very good however if the material on which the LED structure is built is a poor conductor of heat, such as Sapphire or Silicon, then the overall efficacy of the system is in question.

SemiLEDs uses copper alloy, an excellent conductor of heat, thus eliminating the bottleneck effect.

The effects of SemiLEDs efficient Copper alloy devices can be felt in the lifetime and light quality of packaged chips producing white light.

Packages using SemiLEDs LEDs, as opposed to conventional Sapphire LEDs, maintain initial CCT values over time.

Packages using Sapphire LEDs experienced a CCT shift of more than 20% towards the blue end of the spectrum, while packages using SemiLEDs LEDs only experienced a CCT shift of 2%.

This is due to the heat effects on the phosphor chemistry.

For more details; see ![]()